Standards of Practice

Download our standards to see what we inspect

Common Issues Found When Inspecting Homes

Chinese Dry Wall

S-TRAP VS P-TRAP EXPLAINED IN EASY TO UNDERSTAND TERMS

S-TRAP VS P-TRAP EXPLAINED IN EASY TO UNDERSTAND TERMS

Life is full of surprises some are obvious others are hidden from view. These only show up when it is too late to do anything to prevent the impending danger. Chinese drywall is one of these problems lurking in homes across the Deep South. There have been numerous law suits, congressional investigations and misunderstandings concerning Chinese drywall.Here is a short history of the product and the problem. Chinese drywall was imported from 2001 to 2009 and is believed to have been distributed in all 50 states. The areas affected most are in the Deep South; specifically the states of Alabama, Florida, Louisiana, Mississippi, southern Texas and Virginia.The building boom of 2000 to 2006 combined with 9 hurricanes that hit Florida in 2004 and 2005 and Hurricane Katrina that hit the gulf coast in 2005 caused a shortage of domestic drywall. The shortage lasted until 2009 when domestic supplies caught up with demand and problems surfaced with the imported product.

How do I know if I have Chinese drywall?

Unfortunately there is no reliable method for home owners to determine if they have Chinese drywall in their home. Even if the dry wall is stamped made in China or has Chinese markings it may not be bad. Even worse some homes may contain a mixture of domestic and imported drywall.Although high humidity and high temperatures are the common link to the drywall failures. Home owners in northern states are not immune from this problem. All home owners should follow the following suggestions from the Consumer Product Safety Commission to determine if they might have a problem;Step One: A visual inspection must show:

a. Blackening of copper electrical wiring and/or air conditioning evaporator coils and

b. Drywall installed between 2001 and 2009

If both of these are present, look for corroborating evidence.Step Two: Corroborating Evidence: (if drywall was installed between 2005 and 2009, must have at least two of the below. For installations between 2001 and 2004, at least four of the following conditions must be met:)

a. Elemental sulfur in the drywall core (requires outside lab testing)

b. Copper sulfide on coupons, grounding wires, and/or air conditioning coils (requires outside lab testing)

c. Chinese markings on drywall (This does not imply that all Chinese drywall or that only Chinese drywall is associated with these problems. But that among homes with the characteristic corrosion, Chinese drywall is a corroborating marker for the characteristic problems.) Such markings may not be present or easily discerned in all problem drywall homes.

d. Elevated sulfide gas emissions from drywall (requires outside lab testing)

e. Corrosion induced by drywall in test chambers (requires outside lab testing)Additional indicators would be a black ash type corrosion on copper air conditioner “A” coils and electrical wiring. Normal copper corrosion will be reddish or greenish in color. If you suspect you may have Chinese drywall you can contact the Consumer Product Safety commission or the Chinese Drywall Complaint Center for more information.

Some of the information for this article came from the following sources;

http://www.cpsc.gov/en/Safety-Education/Safety-Education-Centers/Drywall-Information-Center/How-can-I-tell-if-my-home-has-problem-drywall/

http://chinesedrywallcomplaintcenter.com/indications.htm

http://en.wikipedia.org/wiki/Chinese_drywall

S-TRAP VS P-TRAP EXPLAINED IN EASY TO UNDERSTAND TERMS

S-TRAP VS P-TRAP EXPLAINED IN EASY TO UNDERSTAND TERMS

S-TRAP VS P-TRAP EXPLAINED IN EASY TO UNDERSTAND TERMS

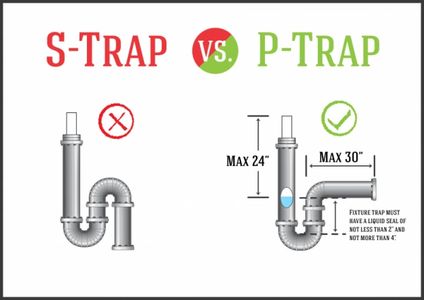

The S-trap is no longer allowed in new construction

Years ago most plumbing codes banned S-trap configurations in favor of P-trap style fixtures. S-traps are no longer used in modern plumbing because on rare occasions with just the right conditions the water can be sucked out of the trap allowing sewer gas to enter your home. The risk from sewer gas can be much worse than just that terrible smell. Sewer gases can be poisonous or even explosive and are not to be treated lightly.S-trap failure requires a large amount of water to flow quickly past the trap. This is usually caused by allowing a sink full of water to drain rapidly. The easy fix is to always refill the trap with water after using the sink. Plumbing codes, however do not allow for common sense fixes, they are designed to makes things work as predictably as possible. Years ago most plumbing codes banned S-trap configurations in favor of P-trap style fixtures. S-trap fixtures are most often found in older homes and homes remodeled by do-it-yourselfers .On the other hand if your house does have S-traps it is not a major concern, most people will never experience a sewer gas smell. The perfect solution would be to tear out the wall and install a vent stack that would go through the roof. Luckily there are three other things you can do:

• It is probably OK to do nothing as long as you do not have a problem

• You can install an Auto Air Vent (AAV)

• You can modify an S-trap to work similar to a P-trap

Here are two possible S-Trap solutions

The AAV is usually frowned on by most plumbing codes but may be the only answer short of tearing out the walls and ceilings to run a vent through the roof. Many different styles of AAV are available starting at $10 and S-trap to P-trap conversion kits are available from hardware and home improvement stores for $30 TO $40. Please note, proper stack venting is always preferred to alternate methods when possible.

an AAV valve is one solution

Another solution is to change the s-trap to a modified p-trap by extending the trap arm to a maximum of 2 1/2 time the diameter of the drain line (3 1/4″ for 1 1/4 and 3 3/4″ for 1 1/2 drain lines). Neither fix is allowed by most plumbing codes for new construction. The alternative however is much more palatable than tearing out the wall and busting a hole in the roof for a proper vent.a modified P-trap is a better solution

a modified P-trap is a better solution to replace a s-trap

Properly maintained s-traps do not necessarily need to be replaced, however there are acceptable solutions should you experience sewer gas odors.

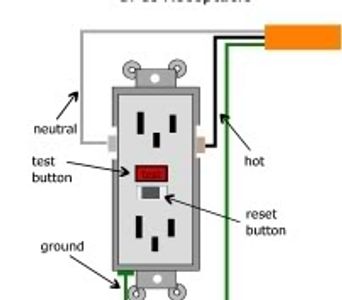

GFCI, GROUND FAULT CIRCUIT BREAKERS

GFCI, GROUND FAULT CIRCUIT BREAKERS

GFCI, GROUND FAULT CIRCUIT BREAKERS

A $15 Ground Fault Circuit Interrupter (GFCI) could save your life, Don’t put it off any longer.

One of the most often listed defects found by home inspectors, building code officers and city occupancy officials is lack of ground fault circuits interrupters or GFCI outlets and breakers.

GFCI receptacle and breaker

Where should you install GFCI outlets? GFCIs are required by the National Electrical Code (NEC) in all new kitchens, bathrooms. crawl spaces, unfinished, basements, and outdoor receptacles. Owners of older houses can retrofit $15 GFI outlets at those locations or have GFI breakers (about $50) mounted in the main breaker panel. Portable GFI adapters, which plug into regular wall receptacles, are available for $20 to $40.

Installing a GFCI could save your life

GFCI protection could prevent as many as two hundred deaths by electrocution every year as well as countless unnecessary burns and fires. The GFCI circuit was first invented in 1961 and has been slowly incorporated into the NEC. GFCI protection for receptacles has been required by the NEC since:

- 1973 Outdoor receptacles

- 1975 Bathrooms

- 1978 Garages

- 1987 Kitchens

- 1990 Crawl spaces and unfinished basements

- 1993 Wet bar sinks

- 2005 Laundry and utility sinks

GFCI protection is required in any area that is within six feet of a water source or over wet surfaces. Metal sinks should be included in this measurement. Wet surfaces include surfaces that may become wet and provide and open source to ground such as wet garage or basement floors. Finished basements with carpet are usually exempted. GFCI protection for outdoor receptacles is required regardless of the floor type.Please do not confuse fuses and standard circuit breakers with GFCIs. Fuses and standard circuit breakers work on the principle of failing when more current flows through a circuit than it was designed to carry. A typical house circuit is a number 12 wire protected by a 20 amp fuse or breaker. Which will melt (trip for breakers) before the wire overheats and causes a fire hazard.Unfortunately a very small amount of current will kill a person who is in contact with a source of grounding. Such as the kitchen faucet or wet concrete without tripping a breaker or blowing a fuse.A GFI receptacle or GFI circuit breaker monitors the flow of electricity between the hot, neutral and ground wires 30 to 40 times per second and will trip (disconnect) the circuit when a difference of as little as .005 amps is detected. (that’s not enough to power a flashlight).The third wire (ground wire) found on many tools and appliances is only effective for larger current leaks and is not sufficient protection for use in wet areas. Many hand held appliances such as hair dryers and curling irons that are typically used around water sources have GFI protection built into the power cord.The third wire on your small appliance or power tool is the ground wire.The ground wire is there to provide a low impedance path to ground, preventing the equipment user from becoming the ground path. Thus providing protection to the user from electrical shock. The ground wire is typically connected to the outer case of your tool or appliance so if a current leak occurs it will trip the GFCI.

Older homes should be updated

Circuits installed before the late 60’s probably do not have the protection of a grounding Circuit. The NEC allows GFCIs to be used to upgrade older two-prong (non-grounded) outlets to three-prong (grounded) outlets without installing any new wire. The use of two prong to three prong adapters and replacing two prong with three prong non grounded receptacles is not encouraged.When the GFCI is installed in a two wire circuit it must have a label that says “No Equipment Ground” on the GFCI outlet and all downstream outlets. Please note most GFCI testers will not trip the GFCI if a ground wire is not present

You may want to install a grounded circuit for your sensitive electronic products. Many electronic products such as computers and big screen TVs use the ground wire as a means of dissipating static electricity.

Inspection FAQs

GFCI, GROUND FAULT CIRCUIT BREAKERS

GFCI, GROUND FAULT CIRCUIT BREAKERS

- Q Are you and your inspectors licensed by the State of Alabama?

A All of our inspectors are trained and licensed by the State of Alabama and take extended training throughout the year. - Q Do you have errors and omissions and liability insurance?

A Yes - Q Can you provide references?

A Visit our web site at http://www.stevenshomeInspection.com - Q What professional organizations do you belong to?

A We are a member ASHI, American Society of Home Inspectors

InterNACHI , The International Association of Certified Home Inspectors i - Q Is it OK to attend the inspection?

A Not only is it OK to attend, we highly encourage it. We feel strongly that the buyer should be present for the complete inspection. Most inspections will take about an hour pr 1000 sqft, if you need to leave you can leave us a cell phone number and we will contact you when we are finished - Q Do you provide repair services?

A No, it is considered unethical for an inspector to perform repairs or profit from suggested repairs within one years of an inspection they have performed - Q How soon can you schedule an inspection?

A. We try to accommodate your schedule, we work seven days a week and evenings, most inspections can be completed within 3 days. - Q What are your charges?

Inspections start at $250 based on square footage, detached garage or a crawl space. Veterans and first responders receive special discounts. - Q How soon will I get the results of my inspection?

A. within 24 hours of the inspection but usually the same day. You will be emailed a digital copy that you can use to e-mail the information and or pictures to friends and relatives..

ASHI Standards of Practice (pdf)

DownloadCopyright © 2025 Stevens Home Inspections - All Rights Reserved.